PRECISION NDT

ANYWHERE INSTANTLY

ANYWHERE INSTANTLY

In industrial manufacturing, absolute reliability is paramount. Our digital X-ray systems for Non-Destructive Testing reveal critical defects in welds, castings, and composites—ensuring uncompromising quality where material failure is not an option.

EFFICIENT WORKFLOW. Better decisions.

Leonardo DR

Equipped with quality standards

The Leonardo DR System brings the X-ray lab directly to the pipeline or onto the lattice mast. Whether as an ultra-light backpack system for industrial climbers or as a robust case station, you consistently receive the same standardized image quality and software performance for quick, secure decisions.

The Leonardo DR System brings the X-ray lab directly to the pipeline or onto the lattice mast. Whether as an ultra-light backpack system for industrial climbers or as a robust case station, you consistently receive the same standardized image quality and software performance for quick, secure decisions.

ISO-Compliant Precision

Meet the highest industry standards (e.g., ISO 17636) directly in the field. Our detectors provide high-resolution images (100µm) that reveal even the finest cracks, pores, or corrosion in welds and castings.

ISO-Compliant Precision

Meet the highest industry standards (e.g., ISO 17636) directly in the field. Our detectors provide high-resolution images (100µm) that reveal even the finest cracks, pores, or corrosion in welds and castings.

ISO-Compliant Precision

Meet the highest industry standards (e.g., ISO 17636) directly in the field. Our detectors provide high-resolution images (100µm) that reveal even the finest cracks, pores, or corrosion in welds and castings.

Immediate Diagnosis

Minimize downtime. Instead of waiting hours for film development, view the digital X-ray image instantly on the screen. Analyze, document, and share results in real-time.

Immediate Diagnosis

Minimize downtime. Instead of waiting hours for film development, view the digital X-ray image instantly on the screen. Analyze, document, and share results in real-time.

Immediate Diagnosis

Minimize downtime. Instead of waiting hours for film development, view the digital X-ray image instantly on the screen. Analyze, document, and share results in real-time.

Universal Flexibility

A system for all scenarios. Use the same detectors and software in both the compact nano-backpack for hard-to-reach areas and the mini-case station for serial inspections on the ground.

Universal Flexibility

A system for all scenarios. Use the same detectors and software in both the compact nano-backpack for hard-to-reach areas and the mini-case station for serial inspections on the ground.

Universal Flexibility

A system for all scenarios. Use the same detectors and software in both the compact nano-backpack for hard-to-reach areas and the mini-case station for serial inspections on the ground.

Key specs

overview

Leonardo systems combine decades of industry experience with continuous development. All features are derived from real-world scenarios and optimized for fast, precise decision-making.

All specs and features:

Key specs

overview

Leonardo systems combine decades of industry experience with continuous development. All features are derived from real-world scenarios and optimized for fast, precise decision-making.

All specs and features:

Key specs

overview

Leonardo systems combine decades of industry experience with continuous development. All features are derived from real-world scenarios and optimized for fast, precise decision-making.

All specs and features:

01 / 05

Rapid-Response

Mobility

The 9.5 kg system allows for wireless, instantaneous X-ray imaging in security-critical operations with tight time constraints.

01 / 05

Rapid-Response

Mobility

The 9.5 kg system allows for wireless, instantaneous X-ray imaging in security-critical operations with tight time constraints.

01 / 05

Rapid-Response

Mobility

The 9.5 kg system allows for wireless, instantaneous X-ray imaging in security-critical operations with tight time constraints.

Maximize Operational Uptime

Maximize Operational Uptime

Maximize Operational Uptime

Digital high-performance radiography delivers results in real time. Instead of waiting for film development, you can assess welds or components immediately on site – accelerating approval processes and reducing costly production interruptions to an absolute minimum.

Digital high-performance radiography delivers results in real time. Instead of waiting for film development, you can assess welds or components immediately on site – accelerating approval processes and reducing costly production interruptions to an absolute minimum.

Global Standard Compliant

Global Standard Compliant

Global Standard Compliant

Protect the integrity of your infrastructure. Our systems provide high-resolution images that meet the strictest industry standards (e.g., ISO 17636). Detect even the finest hairline cracks or corrosion with certainty, and document results in a fully traceable and audit-proof manner.

Protect the integrity of your infrastructure. Our systems provide high-resolution images that meet the strictest industry standards (e.g., ISO 17636). Detect even the finest hairline cracks or corrosion with certainty, and document results in a fully traceable and audit-proof manner.

Elite German Engineering

Elite German Engineering

Elite German Engineering

Developed and manufactured for the demands of everyday industrial use. With our headquarters in Rostock, we guarantee not only the highest production quality but also long-term spare-parts availability and direct support to safeguard your investment.

Developed and manufactured for the demands of everyday industrial use. With our headquarters in Rostock, we guarantee not only the highest production quality but also long-term spare-parts availability and direct support to safeguard your investment.

Beta 1.0: Try next ray AI Engine

Powering NDT AI Analysis

Automatically analyze cracks, corrosion, and pores. Our AI delivers objective results and prevents human error.

We support security organizations with a portable X-ray solution for clear images and rapid decision-making in real-world operational conditions.

View Demo

Ready for analysis? Test the next ray AI Engine with your own image.

THE NEW STANDARD

AT EVERY LOCATION

Oil & Gas

Teams in the oil and gas industry inspect critical pipelines, welds, and plant components directly on-site. Portable DR systems enable rapid decision-making, reduce downtime, and enhance safety in hazardous environments.

Concrete & Construction

Inspection teams accurately and non-destructively analyze reinforcements, cavities, and material defects in concrete structures. The portable solution enables reliable component assessments directly on-site, ideal for renovations, quality assurance, and safety inspections.

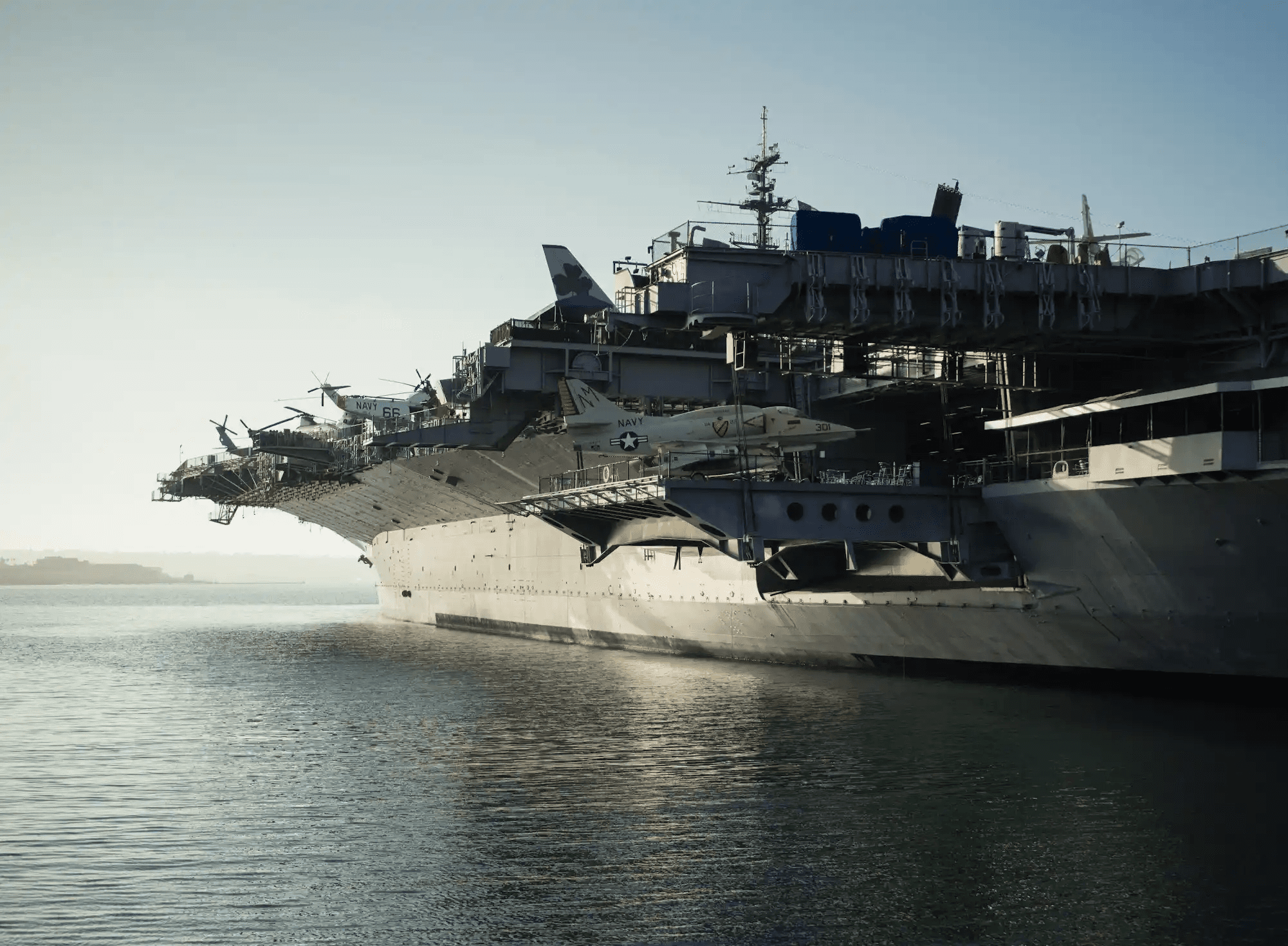

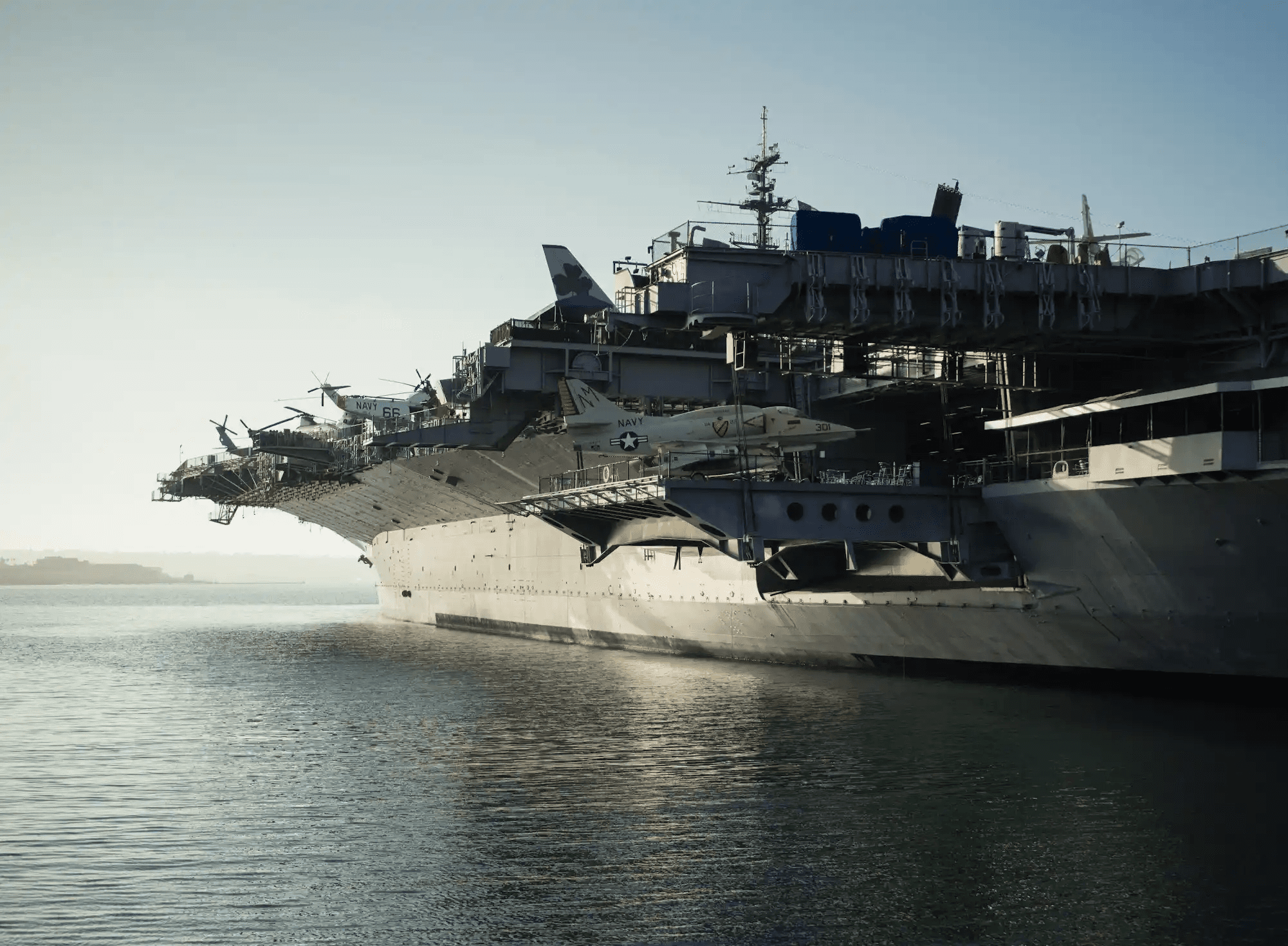

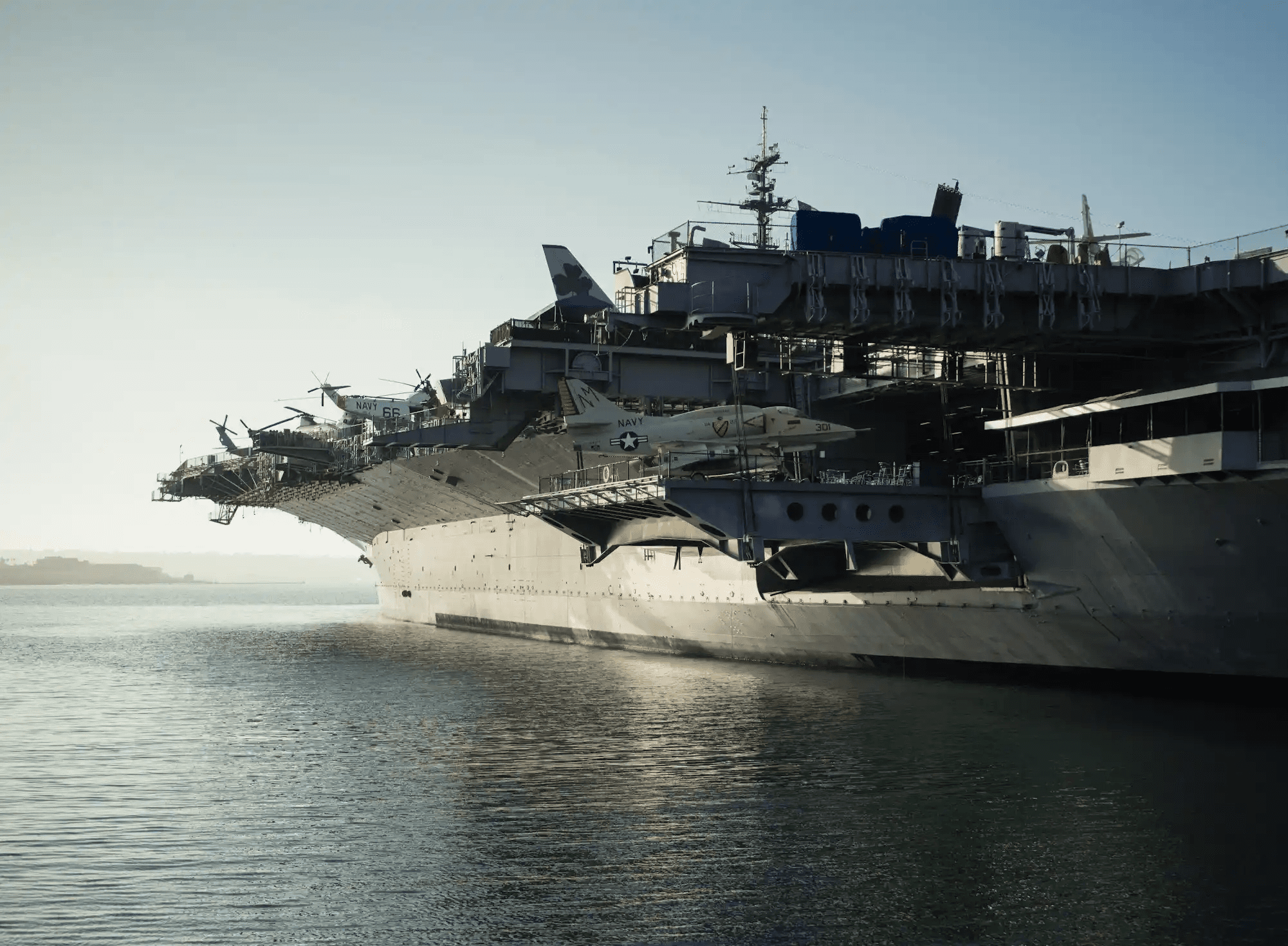

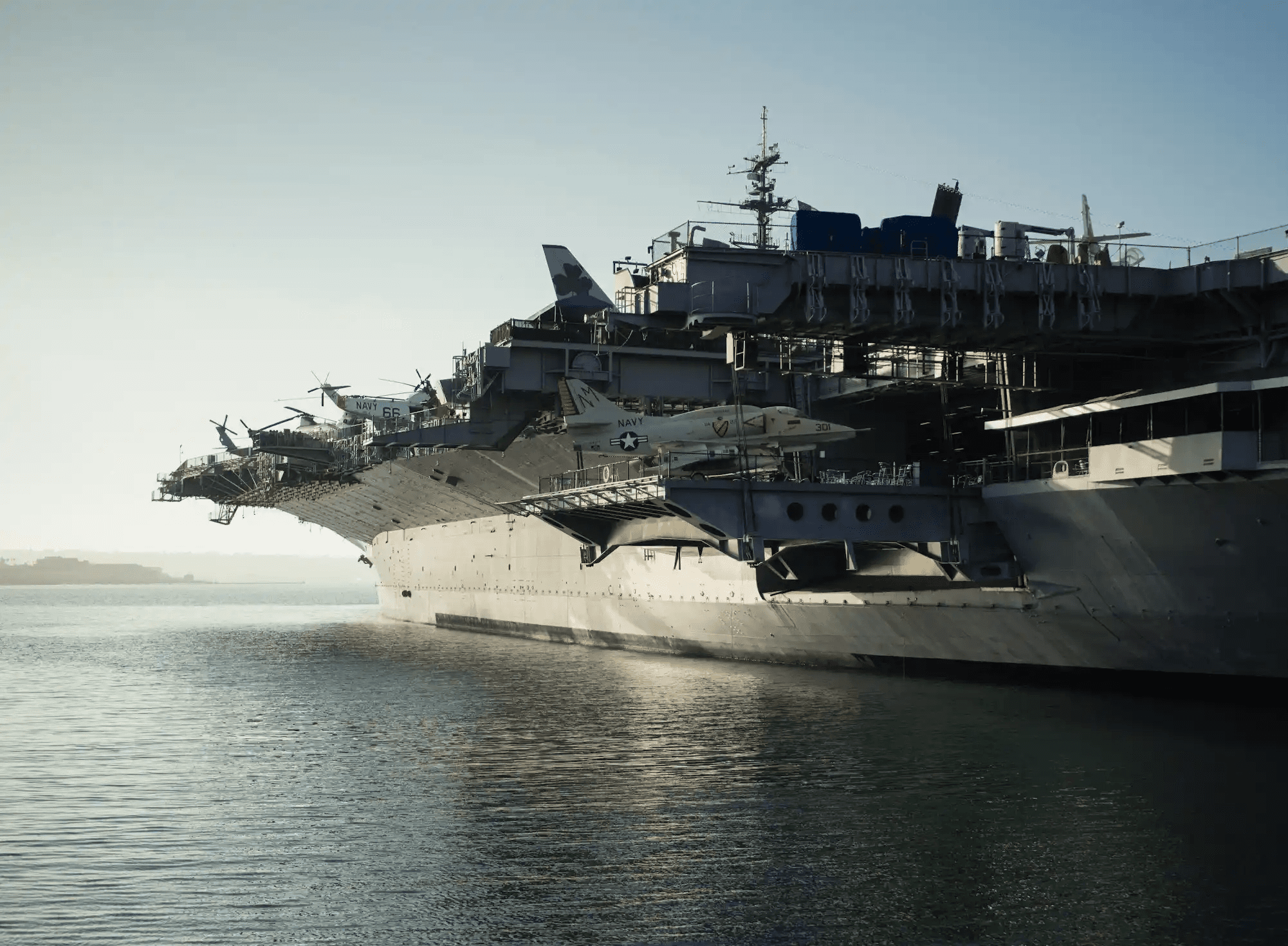

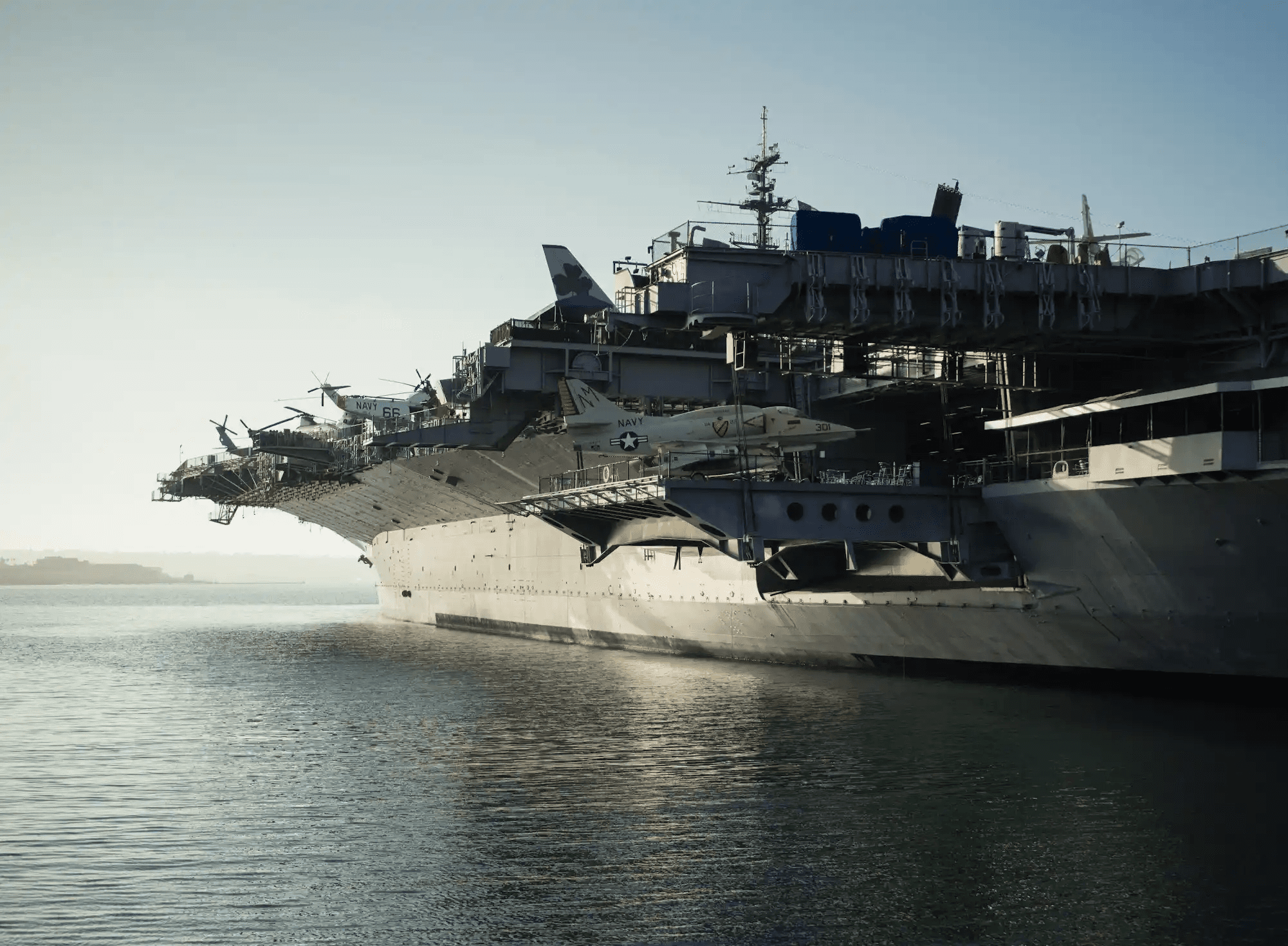

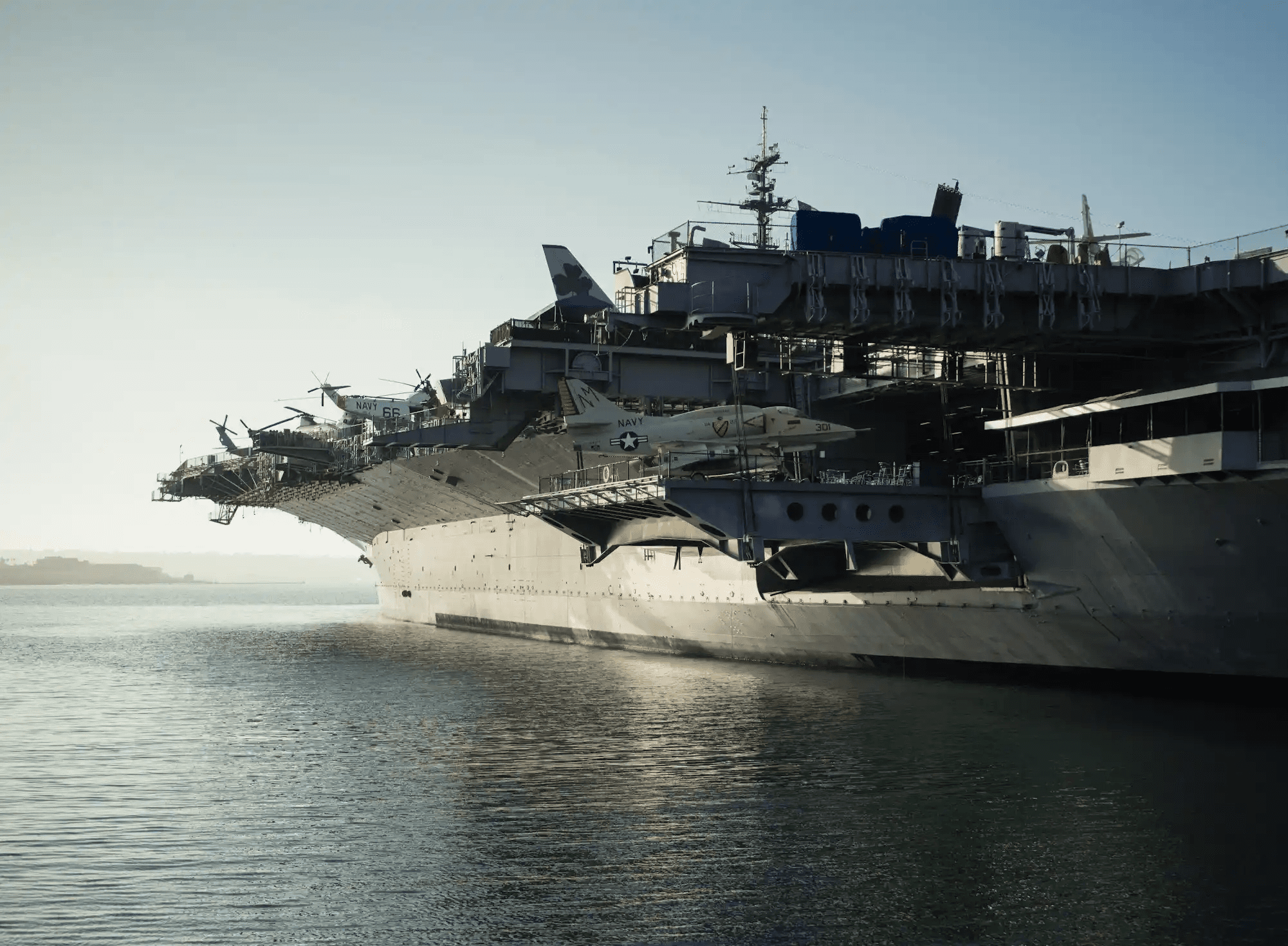

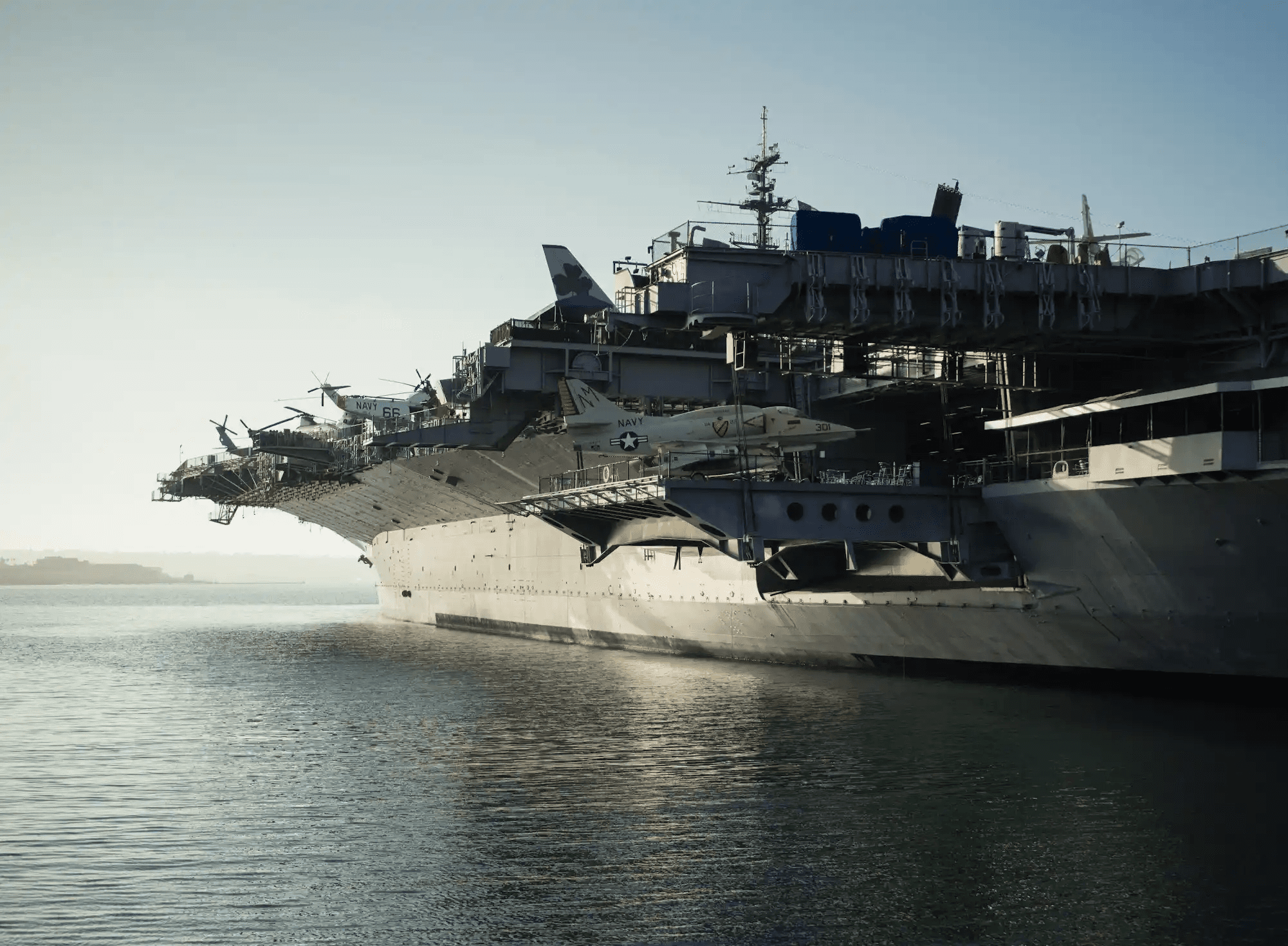

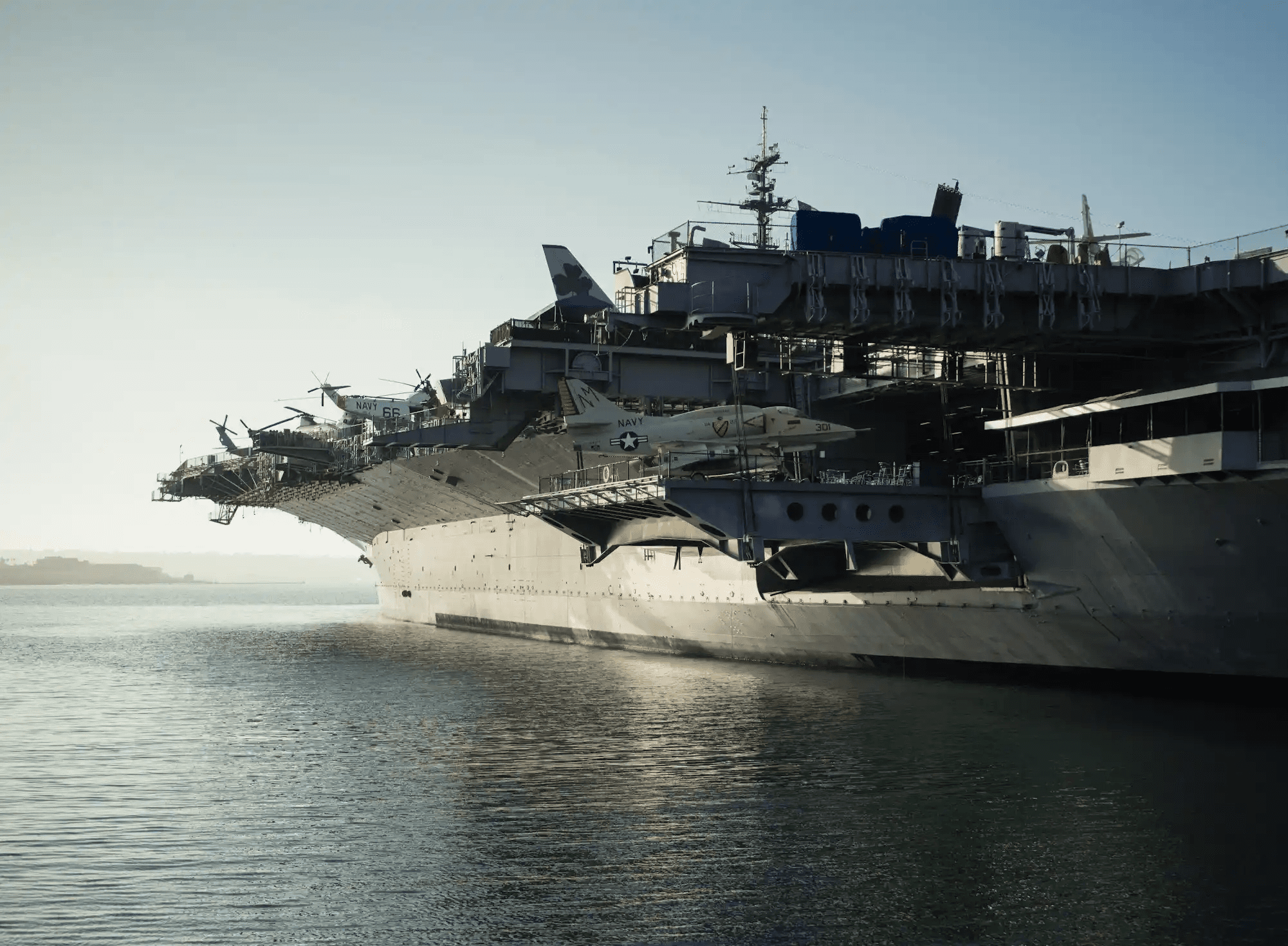

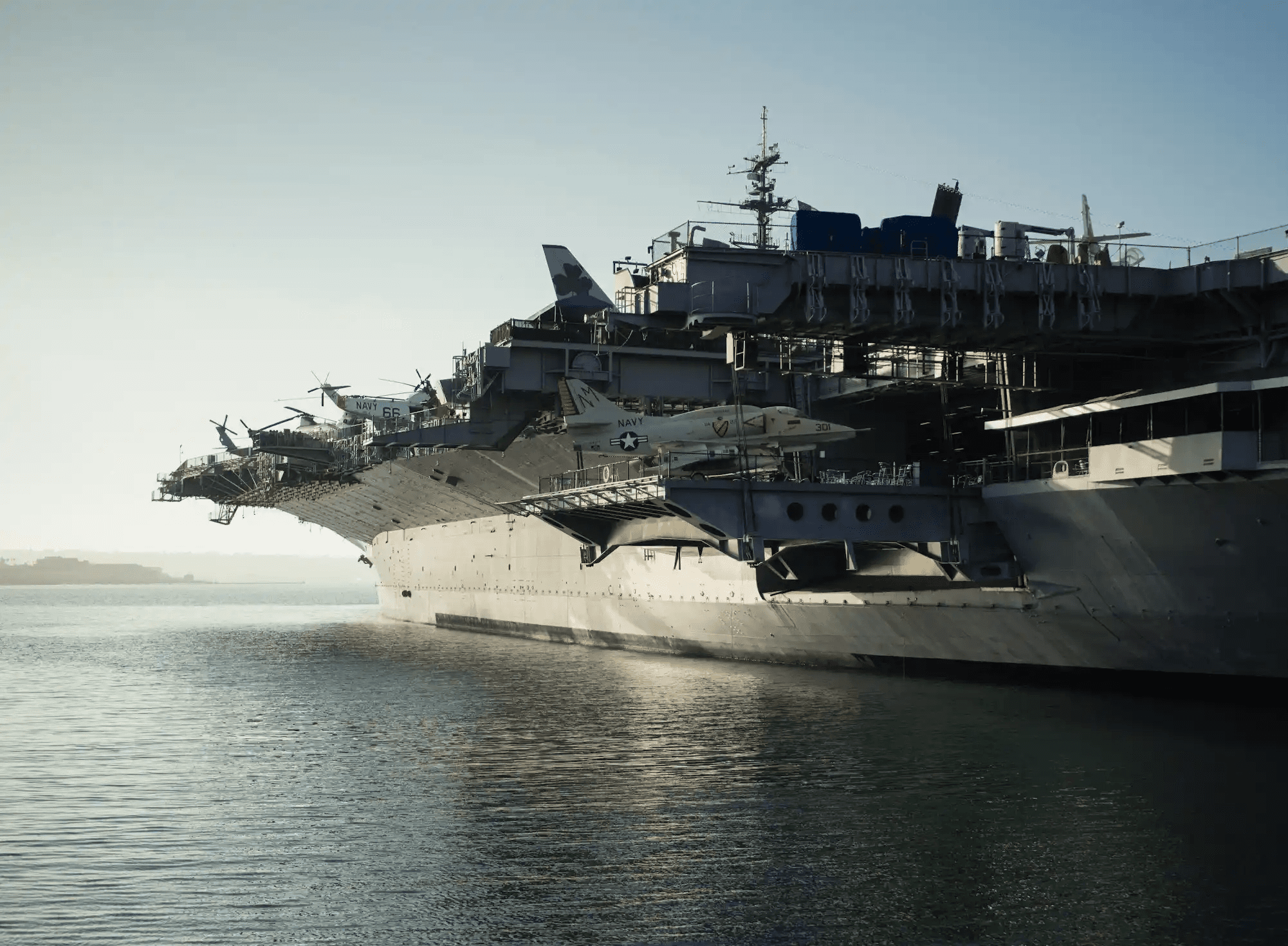

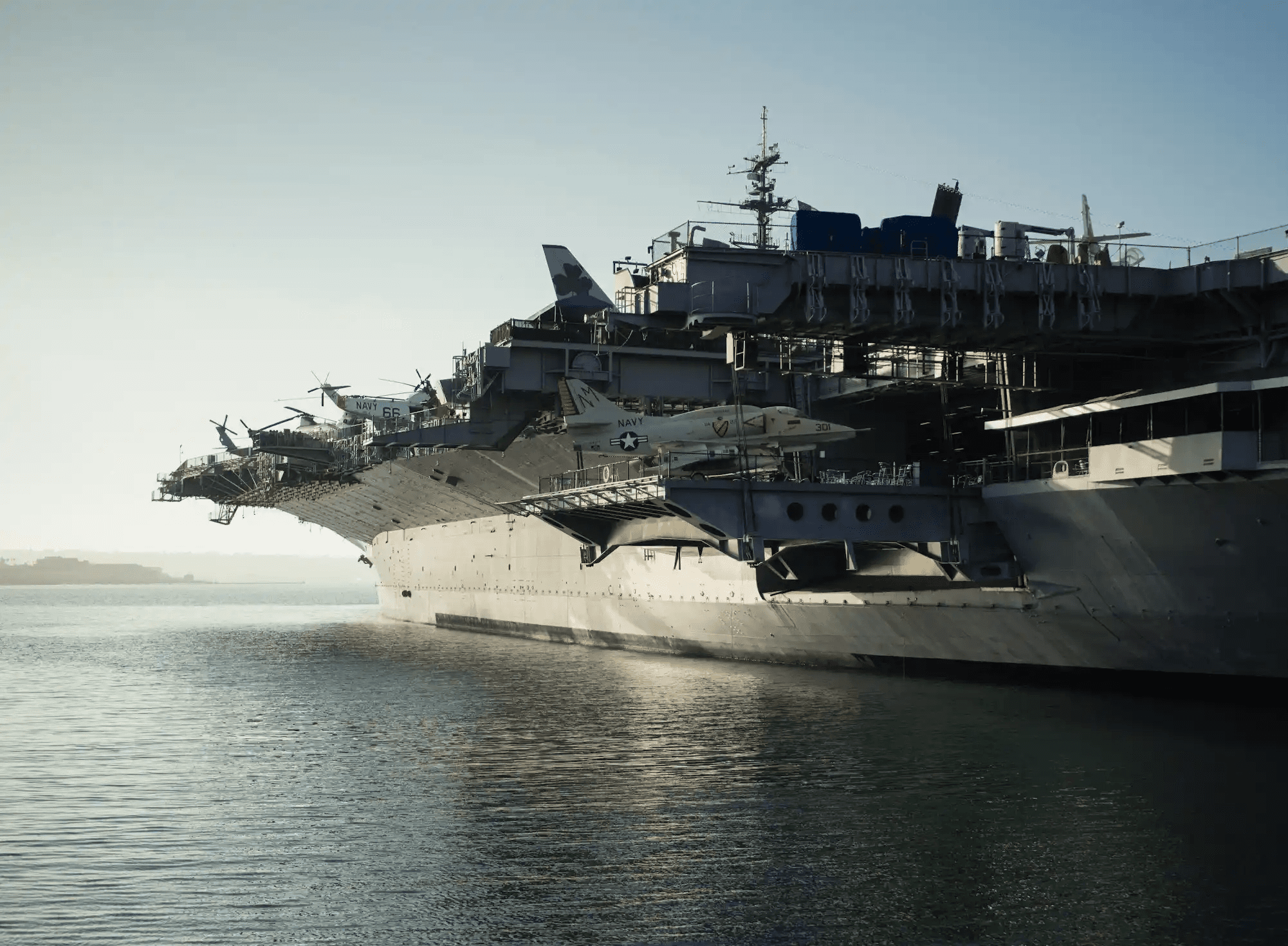

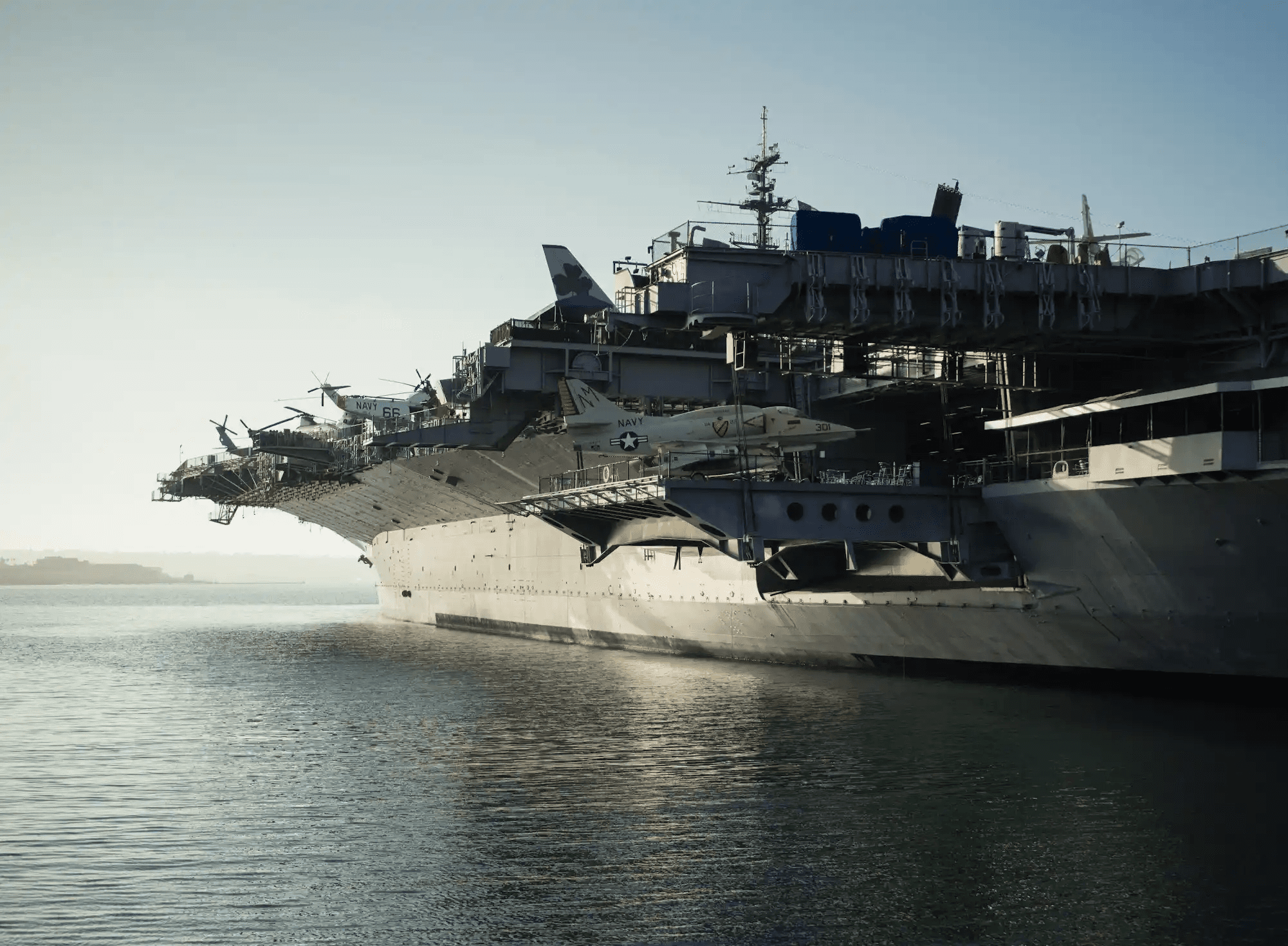

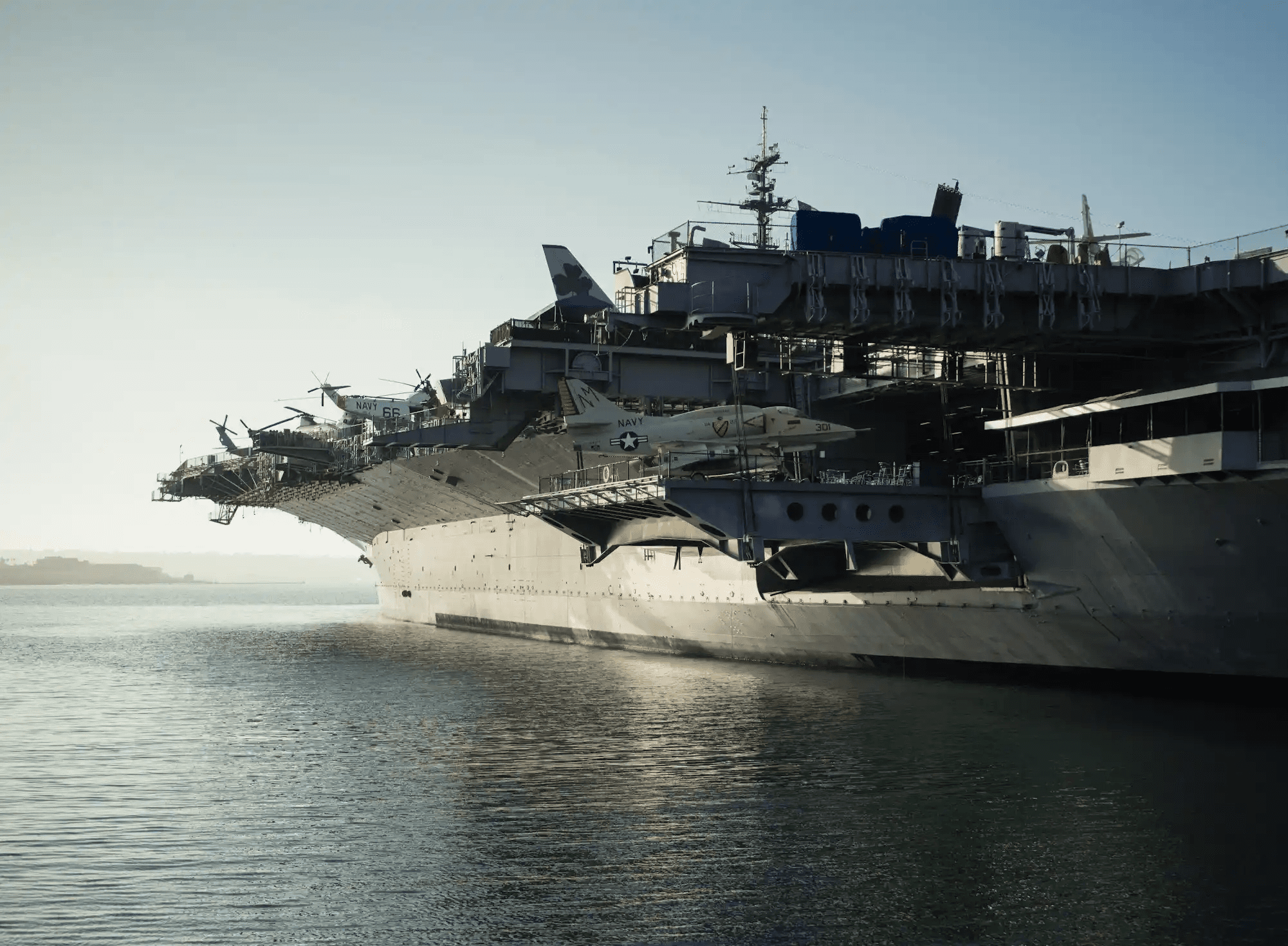

Shipbuilding

Shipyards and maritime service partners inspect weld seams, corrosion areas, and complex structures even in hard-to-reach locations. Portable X-ray technology provides rapid results even in confined spaces, minimizing downtime during dockings.

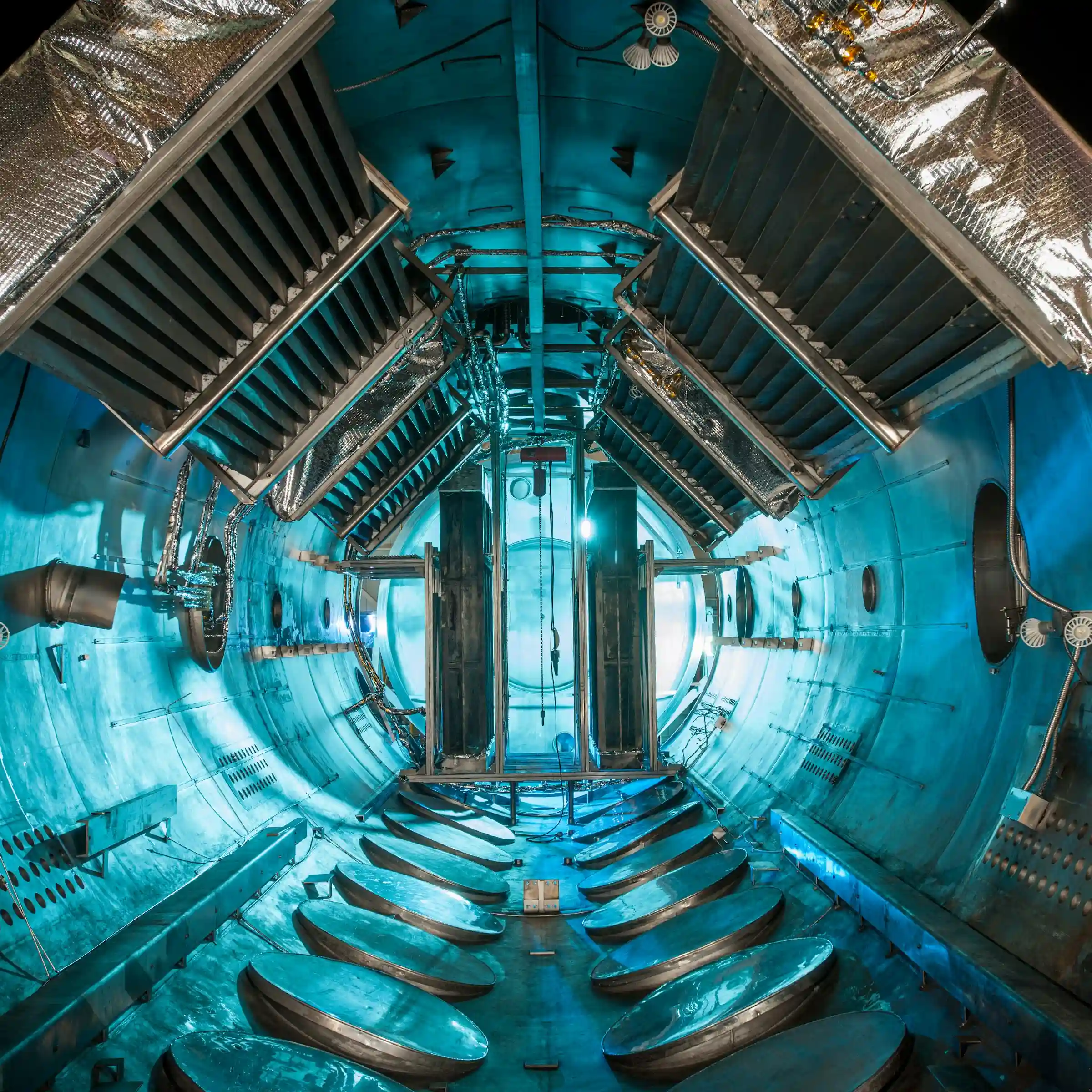

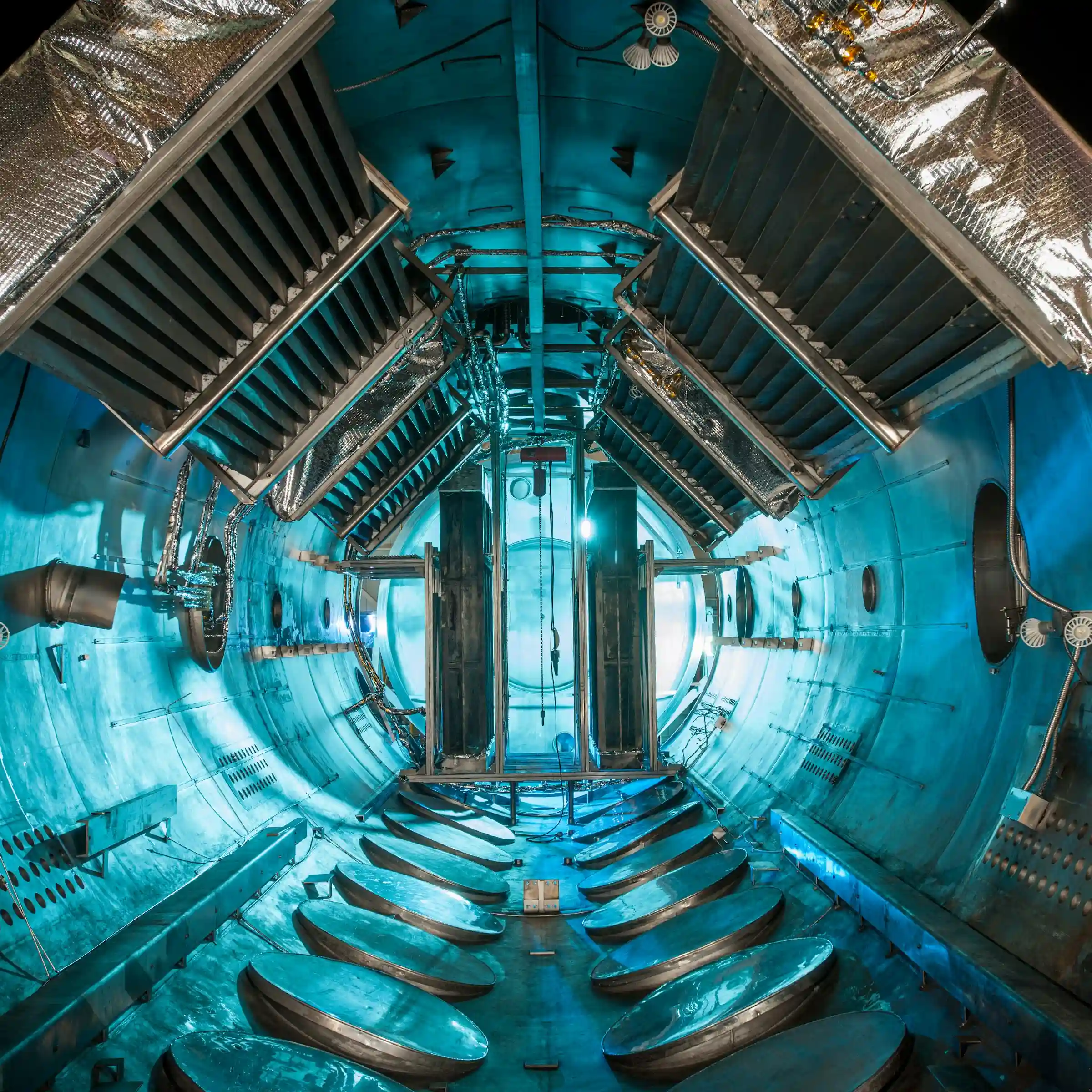

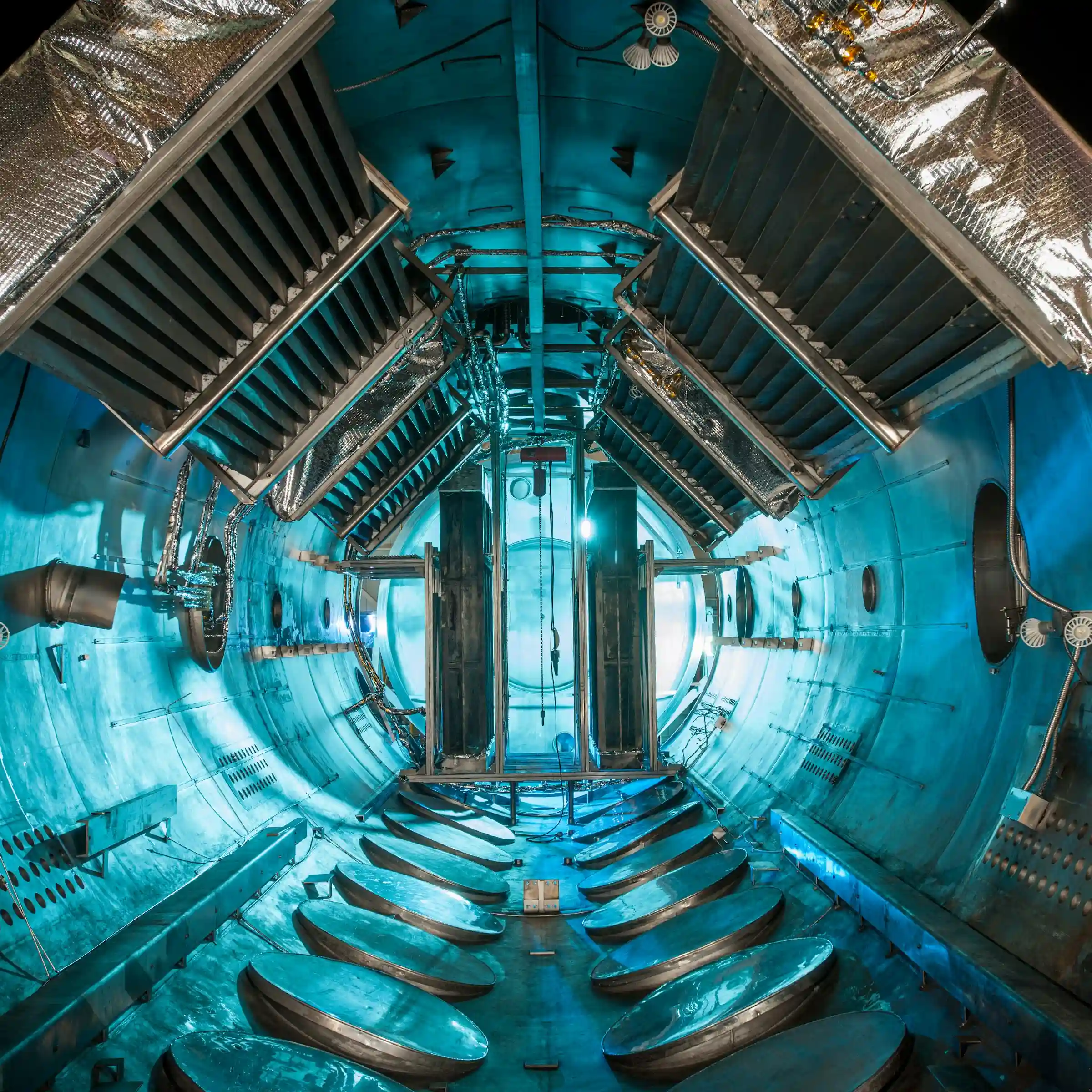

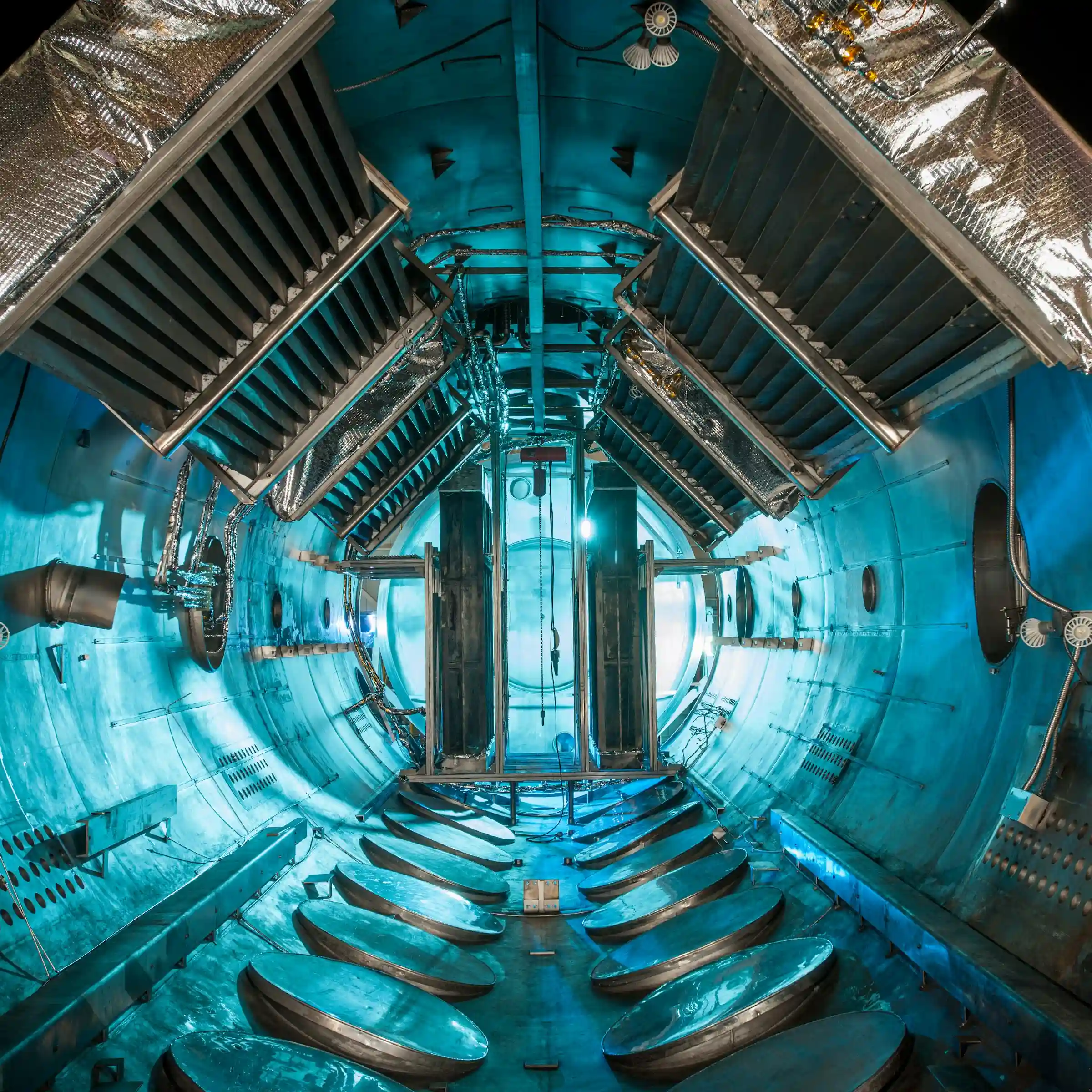

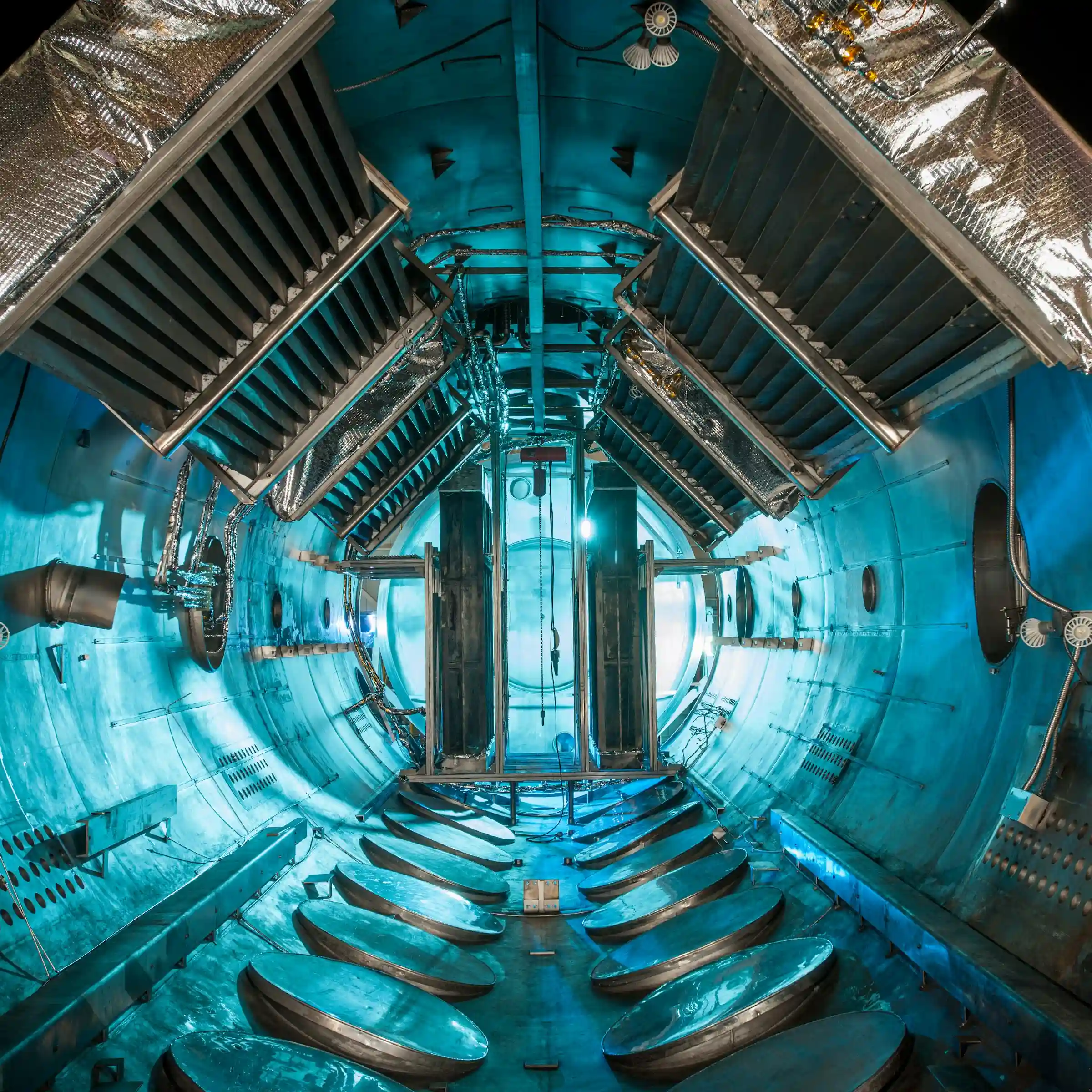

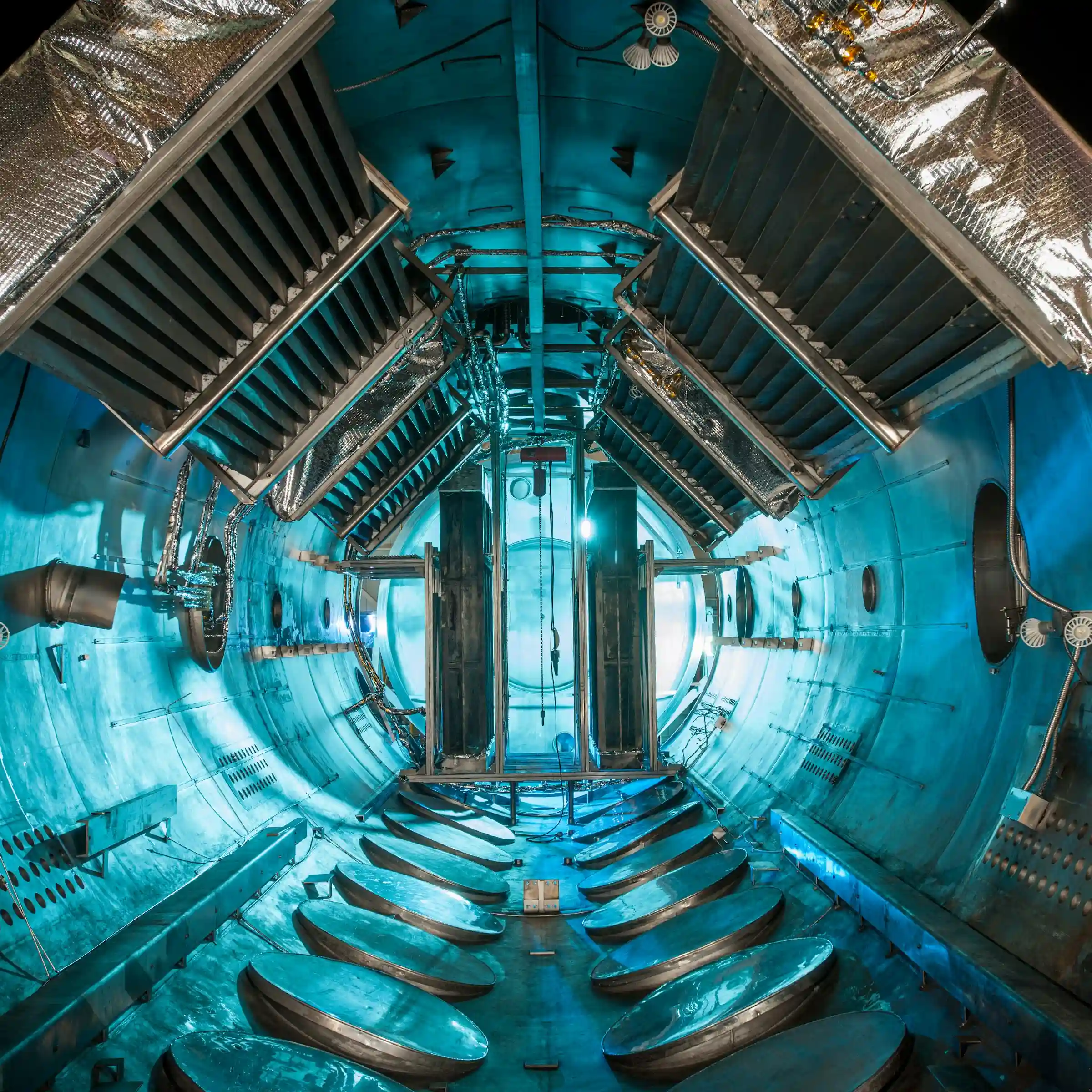

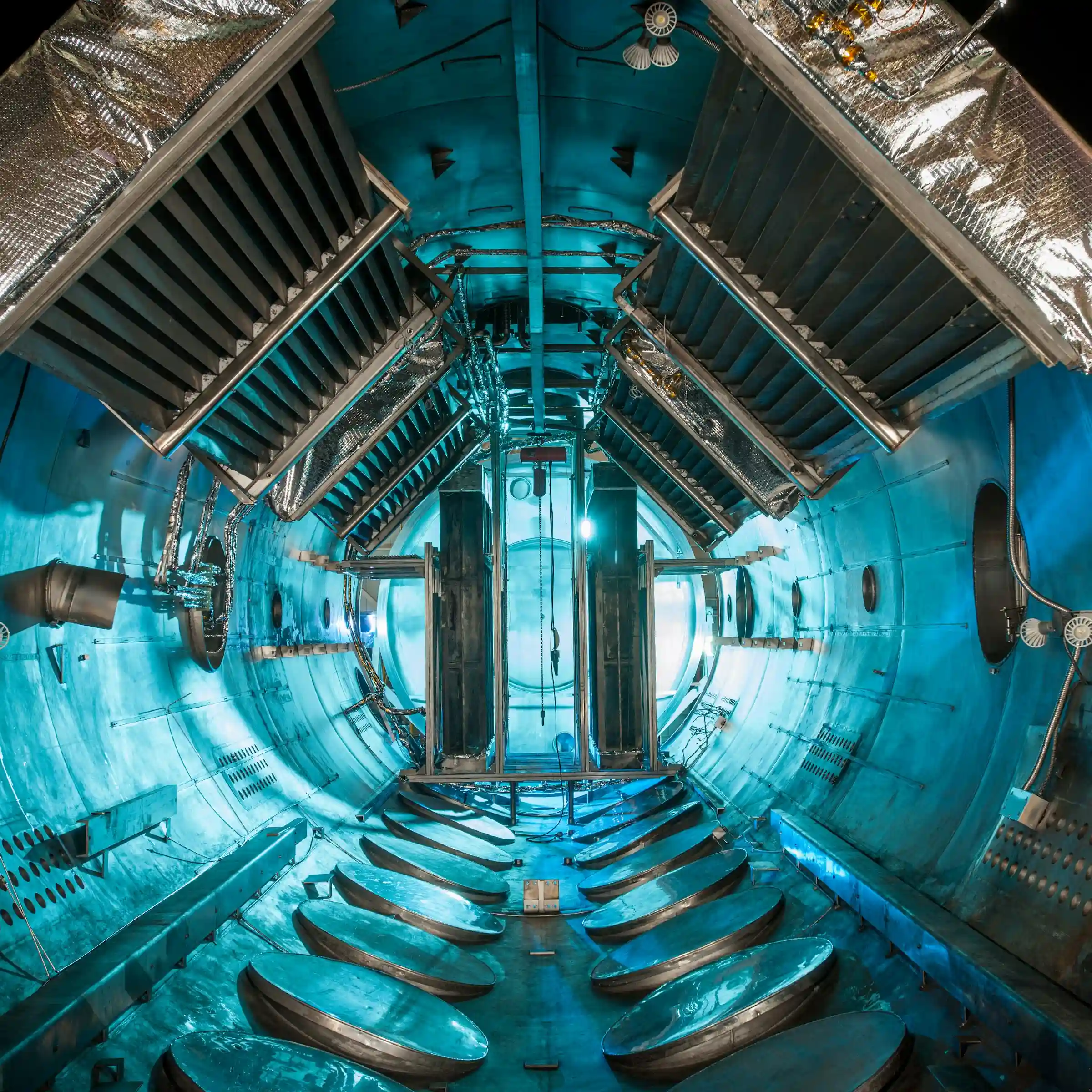

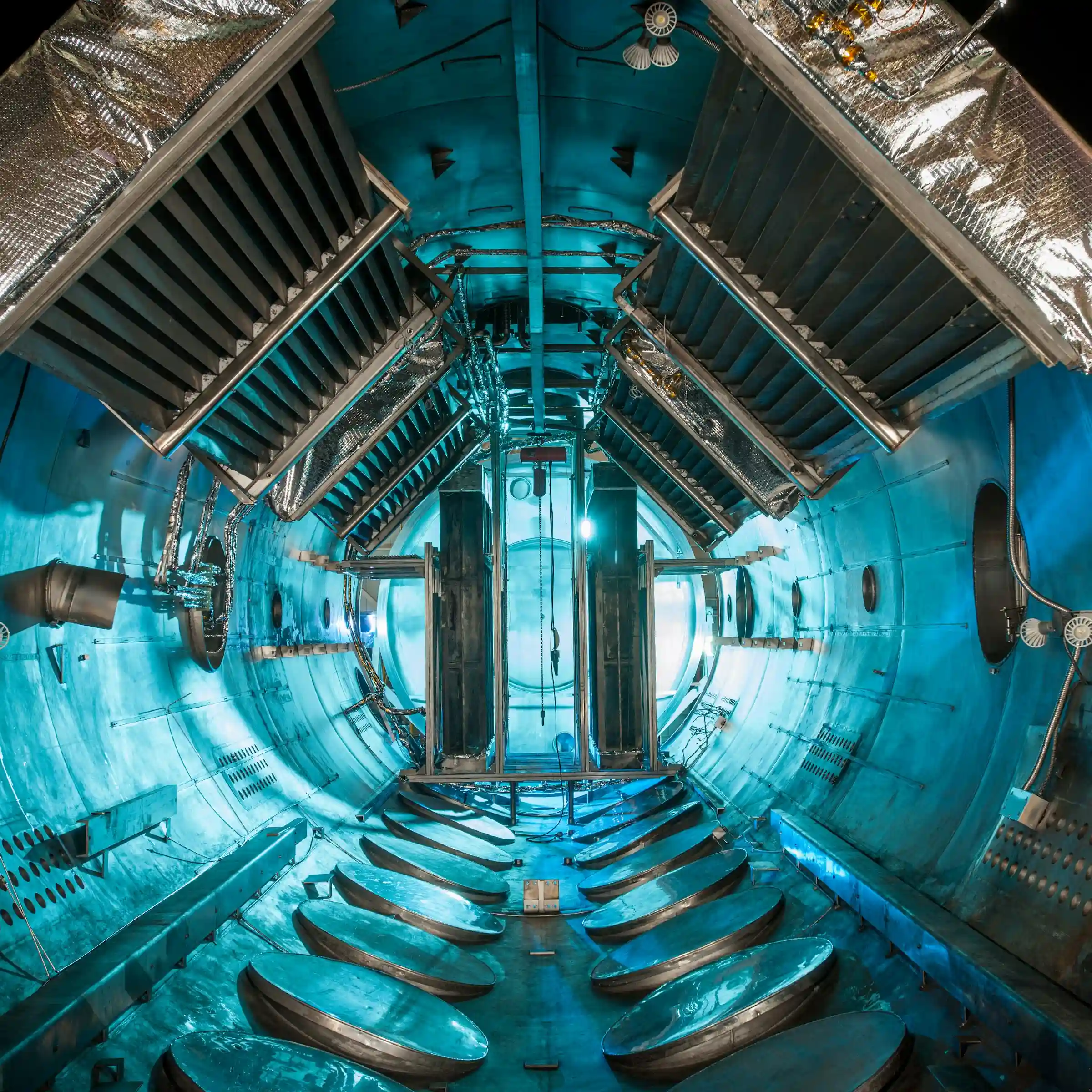

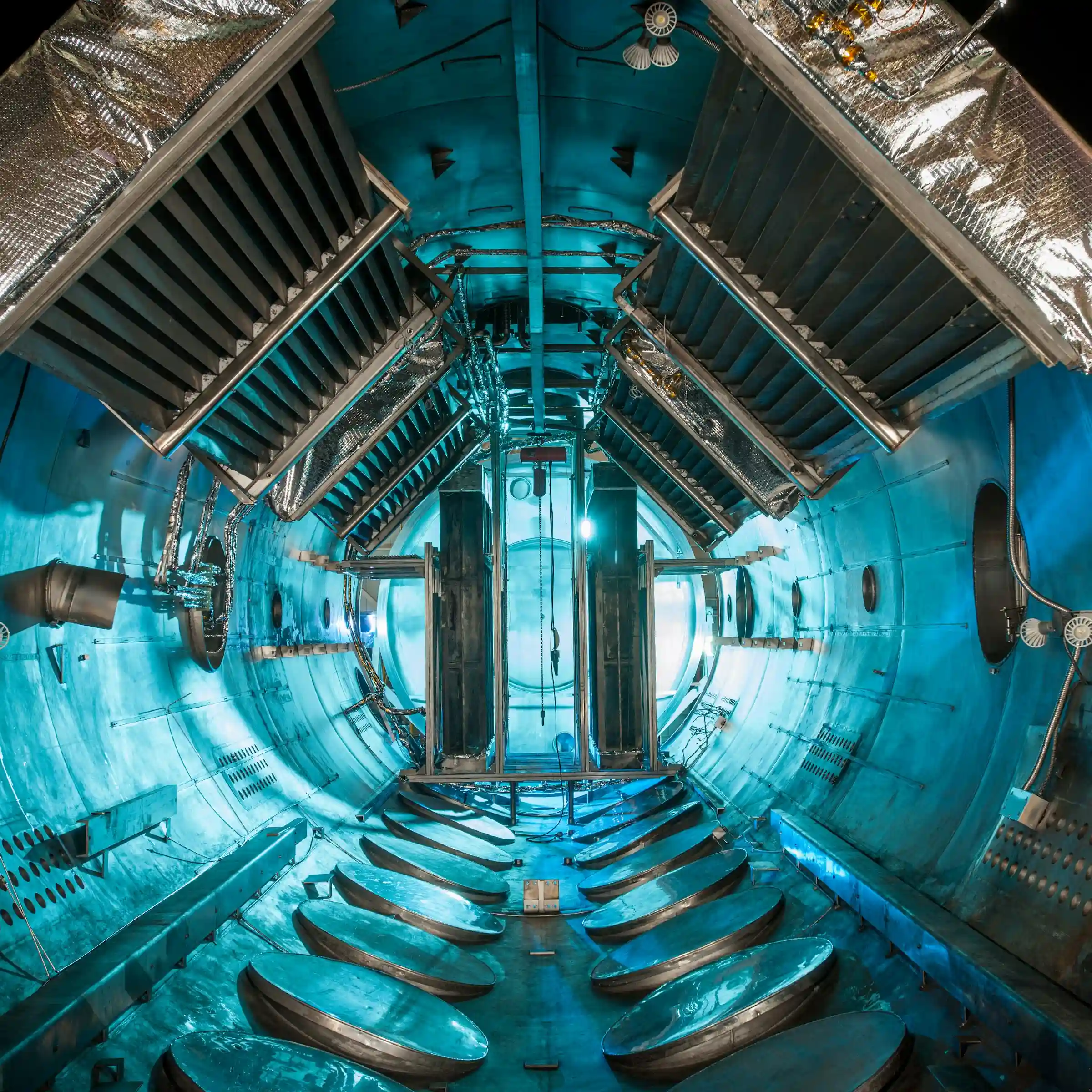

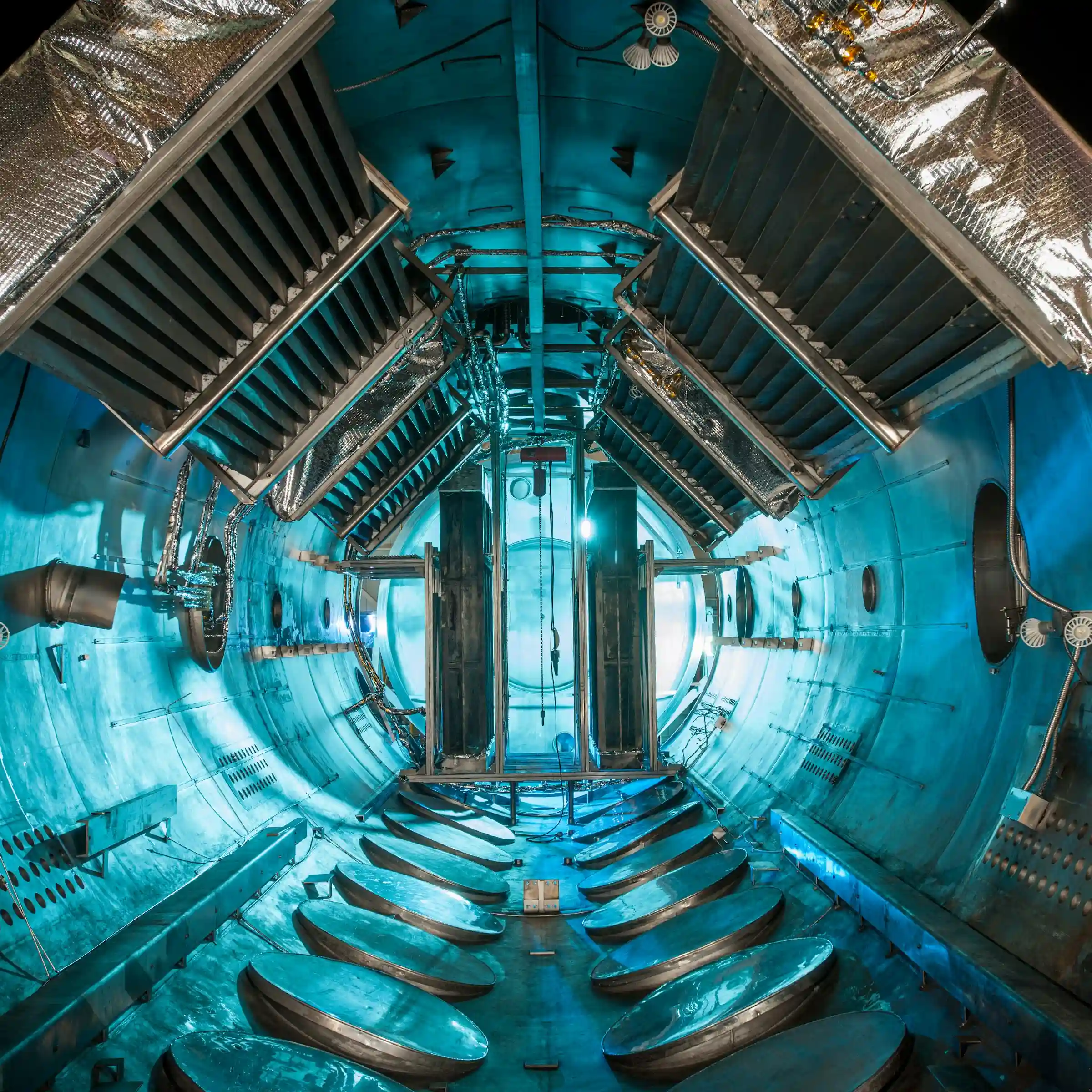

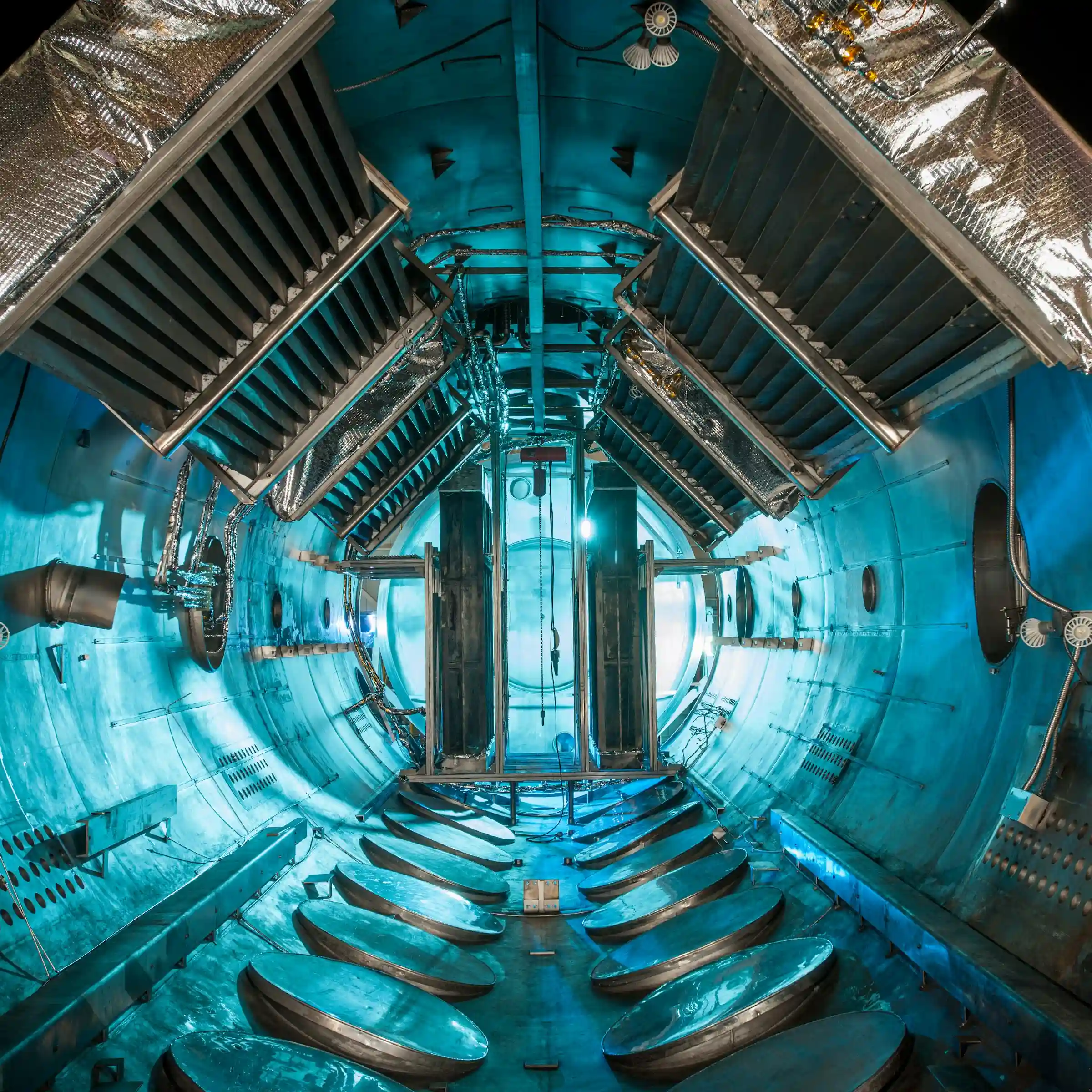

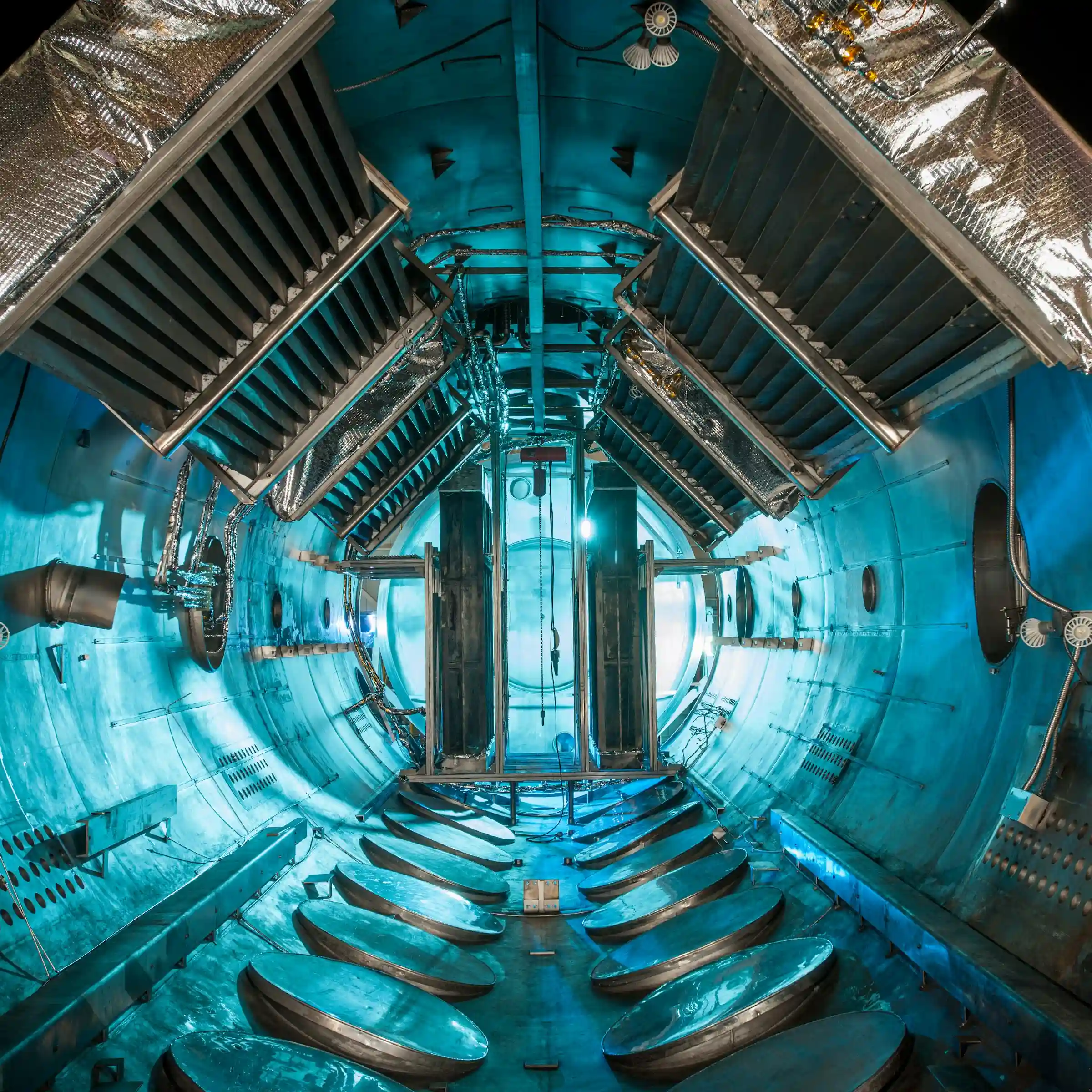

Aerospace

Inspectors gain high-resolution insights into safety-critical components such as engine parts, composites, and welds. Portable DR solutions support standard-compliant inspections, rapid diagnostics, and precise flaw detection—even in the hangar or on-site.

Energy Supply

Inspection teams in power plants and electrical grids examine welds, pipelines, and pressure vessels directly in operation. Portable DR technology enables rapid diagnosis, minimizes downtime, and supports high plant availability.

Oil & Gas

Teams in the oil and gas industry inspect critical pipelines, welds, and plant components directly on-site. Portable DR systems enable rapid decision-making, reduce downtime, and enhance safety in hazardous environments.

Concrete & Construction

Inspection teams accurately and non-destructively analyze reinforcements, cavities, and material defects in concrete structures. The portable solution enables reliable component assessments directly on-site, ideal for renovations, quality assurance, and safety inspections.

Shipbuilding

Shipyards and maritime service partners inspect weld seams, corrosion areas, and complex structures even in hard-to-reach locations. Portable X-ray technology provides rapid results even in confined spaces, minimizing downtime during dockings.

Aerospace

Inspectors gain high-resolution insights into safety-critical components such as engine parts, composites, and welds. Portable DR solutions support standard-compliant inspections, rapid diagnostics, and precise flaw detection—even in the hangar or on-site.

Energy Supply

Inspection teams in power plants and electrical grids examine welds, pipelines, and pressure vessels directly in operation. Portable DR technology enables rapid diagnosis, minimizes downtime, and supports high plant availability.

Oil & Gas

Teams in the oil and gas industry inspect critical pipelines, welds, and plant components directly on-site. Portable DR systems enable rapid decision-making, reduce downtime, and enhance safety in hazardous environments.

Concrete & Construction

Inspection teams accurately and non-destructively analyze reinforcements, cavities, and material defects in concrete structures. The portable solution enables reliable component assessments directly on-site, ideal for renovations, quality assurance, and safety inspections.

Shipbuilding

Shipyards and maritime service partners inspect weld seams, corrosion areas, and complex structures even in hard-to-reach locations. Portable X-ray technology provides rapid results even in confined spaces, minimizing downtime during dockings.

Aerospace

Inspectors gain high-resolution insights into safety-critical components such as engine parts, composites, and welds. Portable DR solutions support standard-compliant inspections, rapid diagnostics, and precise flaw detection—even in the hangar or on-site.

Energy Supply

Inspection teams in power plants and electrical grids examine welds, pipelines, and pressure vessels directly in operation. Portable DR technology enables rapid diagnosis, minimizes downtime, and supports high plant availability.

Oil & Gas

Teams in the oil and gas industry inspect critical pipelines, welds, and plant components directly on-site. Portable DR systems enable rapid decision-making, reduce downtime, and enhance safety in hazardous environments.

Concrete & Construction

Inspection teams accurately and non-destructively analyze reinforcements, cavities, and material defects in concrete structures. The portable solution enables reliable component assessments directly on-site, ideal for renovations, quality assurance, and safety inspections.

Shipbuilding

Shipyards and maritime service partners inspect weld seams, corrosion areas, and complex structures even in hard-to-reach locations. Portable X-ray technology provides rapid results even in confined spaces, minimizing downtime during dockings.

Aerospace

Inspectors gain high-resolution insights into safety-critical components such as engine parts, composites, and welds. Portable DR solutions support standard-compliant inspections, rapid diagnostics, and precise flaw detection—even in the hangar or on-site.

Energy Supply

Inspection teams in power plants and electrical grids examine welds, pipelines, and pressure vessels directly in operation. Portable DR technology enables rapid diagnosis, minimizes downtime, and supports high plant availability.

Oil & Gas

Teams in the oil and gas industry inspect critical pipelines, welds, and plant components directly on-site. Portable DR systems enable rapid decision-making, reduce downtime, and enhance safety in hazardous environments.

Concrete & Construction

Inspection teams accurately and non-destructively analyze reinforcements, cavities, and material defects in concrete structures. The portable solution enables reliable component assessments directly on-site, ideal for renovations, quality assurance, and safety inspections.

Shipbuilding

Shipyards and maritime service partners inspect weld seams, corrosion areas, and complex structures even in hard-to-reach locations. Portable X-ray technology provides rapid results even in confined spaces, minimizing downtime during dockings.

Aerospace

Inspectors gain high-resolution insights into safety-critical components such as engine parts, composites, and welds. Portable DR solutions support standard-compliant inspections, rapid diagnostics, and precise flaw detection—even in the hangar or on-site.

Energy Supply

Inspection teams in power plants and electrical grids examine welds, pipelines, and pressure vessels directly in operation. Portable DR technology enables rapid diagnosis, minimizes downtime, and supports high plant availability.

Oil & Gas

Teams in the oil and gas industry inspect critical pipelines, welds, and plant components directly on-site. Portable DR systems enable rapid decision-making, reduce downtime, and enhance safety in hazardous environments.

Concrete & Construction

Inspection teams accurately and non-destructively analyze reinforcements, cavities, and material defects in concrete structures. The portable solution enables reliable component assessments directly on-site, ideal for renovations, quality assurance, and safety inspections.

Shipbuilding

Shipyards and maritime service partners inspect weld seams, corrosion areas, and complex structures even in hard-to-reach locations. Portable X-ray technology provides rapid results even in confined spaces, minimizing downtime during dockings.

Aerospace

Inspectors gain high-resolution insights into safety-critical components such as engine parts, composites, and welds. Portable DR solutions support standard-compliant inspections, rapid diagnostics, and precise flaw detection—even in the hangar or on-site.

Energy Supply

Inspection teams in power plants and electrical grids examine welds, pipelines, and pressure vessels directly in operation. Portable DR technology enables rapid diagnosis, minimizes downtime, and supports high plant availability.

Oil & Gas

Teams in the oil and gas industry inspect critical pipelines, welds, and plant components directly on-site. Portable DR systems enable rapid decision-making, reduce downtime, and enhance safety in hazardous environments.

Concrete & Construction

Inspection teams accurately and non-destructively analyze reinforcements, cavities, and material defects in concrete structures. The portable solution enables reliable component assessments directly on-site, ideal for renovations, quality assurance, and safety inspections.

Shipbuilding

Shipyards and maritime service partners inspect weld seams, corrosion areas, and complex structures even in hard-to-reach locations. Portable X-ray technology provides rapid results even in confined spaces, minimizing downtime during dockings.

Aerospace

Inspectors gain high-resolution insights into safety-critical components such as engine parts, composites, and welds. Portable DR solutions support standard-compliant inspections, rapid diagnostics, and precise flaw detection—even in the hangar or on-site.

Energy Supply

Inspection teams in power plants and electrical grids examine welds, pipelines, and pressure vessels directly in operation. Portable DR technology enables rapid diagnosis, minimizes downtime, and supports high plant availability.

Oil & Gas

Teams in the oil and gas industry inspect critical pipelines, welds, and plant components directly on-site. Portable DR systems enable rapid decision-making, reduce downtime, and enhance safety in hazardous environments.

Concrete & Construction

Inspection teams accurately and non-destructively analyze reinforcements, cavities, and material defects in concrete structures. The portable solution enables reliable component assessments directly on-site, ideal for renovations, quality assurance, and safety inspections.

Shipbuilding

Shipyards and maritime service partners inspect weld seams, corrosion areas, and complex structures even in hard-to-reach locations. Portable X-ray technology provides rapid results even in confined spaces, minimizing downtime during dockings.

Aerospace

Inspectors gain high-resolution insights into safety-critical components such as engine parts, composites, and welds. Portable DR solutions support standard-compliant inspections, rapid diagnostics, and precise flaw detection—even in the hangar or on-site.

Energy Supply

Inspection teams in power plants and electrical grids examine welds, pipelines, and pressure vessels directly in operation. Portable DR technology enables rapid diagnosis, minimizes downtime, and supports high plant availability.

Oil & Gas

Teams in the oil and gas industry inspect critical pipelines, welds, and plant components directly on-site. Portable DR systems enable rapid decision-making, reduce downtime, and enhance safety in hazardous environments.

Concrete & Construction

Inspection teams accurately and non-destructively analyze reinforcements, cavities, and material defects in concrete structures. The portable solution enables reliable component assessments directly on-site, ideal for renovations, quality assurance, and safety inspections.

Shipbuilding

Shipyards and maritime service partners inspect weld seams, corrosion areas, and complex structures even in hard-to-reach locations. Portable X-ray technology provides rapid results even in confined spaces, minimizing downtime during dockings.

Aerospace

Inspectors gain high-resolution insights into safety-critical components such as engine parts, composites, and welds. Portable DR solutions support standard-compliant inspections, rapid diagnostics, and precise flaw detection—even in the hangar or on-site.

Energy Supply

Inspection teams in power plants and electrical grids examine welds, pipelines, and pressure vessels directly in operation. Portable DR technology enables rapid diagnosis, minimizes downtime, and supports high plant availability.

Oil & Gas

Teams in the oil and gas industry inspect critical pipelines, welds, and plant components directly on-site. Portable DR systems enable rapid decision-making, reduce downtime, and enhance safety in hazardous environments.

Concrete & Construction

Inspection teams accurately and non-destructively analyze reinforcements, cavities, and material defects in concrete structures. The portable solution enables reliable component assessments directly on-site, ideal for renovations, quality assurance, and safety inspections.

Shipbuilding

Shipyards and maritime service partners inspect weld seams, corrosion areas, and complex structures even in hard-to-reach locations. Portable X-ray technology provides rapid results even in confined spaces, minimizing downtime during dockings.

Aerospace

Inspectors gain high-resolution insights into safety-critical components such as engine parts, composites, and welds. Portable DR solutions support standard-compliant inspections, rapid diagnostics, and precise flaw detection—even in the hangar or on-site.

Energy Supply

Inspection teams in power plants and electrical grids examine welds, pipelines, and pressure vessels directly in operation. Portable DR technology enables rapid diagnosis, minimizes downtime, and supports high plant availability.

Oil & Gas

Teams in the oil and gas industry inspect critical pipelines, welds, and plant components directly on-site. Portable DR systems enable rapid decision-making, reduce downtime, and enhance safety in hazardous environments.

Concrete & Construction

Inspection teams accurately and non-destructively analyze reinforcements, cavities, and material defects in concrete structures. The portable solution enables reliable component assessments directly on-site, ideal for renovations, quality assurance, and safety inspections.

Shipbuilding

Shipyards and maritime service partners inspect weld seams, corrosion areas, and complex structures even in hard-to-reach locations. Portable X-ray technology provides rapid results even in confined spaces, minimizing downtime during dockings.

Aerospace

Inspectors gain high-resolution insights into safety-critical components such as engine parts, composites, and welds. Portable DR solutions support standard-compliant inspections, rapid diagnostics, and precise flaw detection—even in the hangar or on-site.

Energy Supply

Inspection teams in power plants and electrical grids examine welds, pipelines, and pressure vessels directly in operation. Portable DR technology enables rapid diagnosis, minimizes downtime, and supports high plant availability.

Oil & Gas

Teams in the oil and gas industry inspect critical pipelines, welds, and plant components directly on-site. Portable DR systems enable rapid decision-making, reduce downtime, and enhance safety in hazardous environments.

Concrete & Construction

Inspection teams accurately and non-destructively analyze reinforcements, cavities, and material defects in concrete structures. The portable solution enables reliable component assessments directly on-site, ideal for renovations, quality assurance, and safety inspections.

Shipbuilding

Shipyards and maritime service partners inspect weld seams, corrosion areas, and complex structures even in hard-to-reach locations. Portable X-ray technology provides rapid results even in confined spaces, minimizing downtime during dockings.

Aerospace

Inspectors gain high-resolution insights into safety-critical components such as engine parts, composites, and welds. Portable DR solutions support standard-compliant inspections, rapid diagnostics, and precise flaw detection—even in the hangar or on-site.

Energy Supply

Inspection teams in power plants and electrical grids examine welds, pipelines, and pressure vessels directly in operation. Portable DR technology enables rapid diagnosis, minimizes downtime, and supports high plant availability.

“The portable solution has significantly accelerated our on-site inspections. Whereas we previously had to employ time-consuming film development, the digital Oehm & Rehbein systems now deliver clear wall thickness and weld seam images in just a few minutes, without any loss of quality and without interrupting the process.”

Inspection Service Provider, Germany

01 / 04

“The portable solution has significantly accelerated our on-site inspections. Whereas we previously had to employ time-consuming film development, the digital Oehm & Rehbein systems now deliver clear wall thickness and weld seam images in just a few minutes, without any loss of quality and without interrupting the process.”

Inspection Service Provider, Germany

01 / 04

“The portable solution has significantly accelerated our on-site inspections. Whereas we previously had to employ time-consuming film development, the digital Oehm & Rehbein systems now deliver clear wall thickness and weld seam images in just a few minutes, without any loss of quality and without interrupting the process.”

Inspection Service Provider, Germany

01 / 04

YOUR CHALLENGE –

Our solution.

We support security organizations and industrial companies with portable X-ray solutions for clear images and quick decisions under real-world operating conditions.

YOUR CHALLENGE

Our solution.

We support security organizations with a portable X-ray solution for clear images and rapid decision-making in real-world operational conditions.

YOUR CHALLENGE –

Our solution.

We support security organizations and industrial companies with portable X-ray solutions for clear images and quick decisions under real-world operating conditions.